Calgary: modular housing by ATCO

Faster and cheaper

‘Akin to Lego’: Homes built in a factory may be ‘next frontier’. Steven Wilhelm, Calgary Herald, July 2025.

Piece by piece, cranes lift 84 prefabricated rentals into place in downtown Calgary. Karina Zapata, CBC News, August 2025. Video.

Modular apartment building in downtown Calgary aims to address housing affordability. Amar Shah, CityNews Calgary.

Finishing touches being put on affordable housing modular project. Stephen Hunt, CTV News.

These stories all describe a project at 1007 6 Ave. S.W. by Attainable Homes Calgary, a city-owned agency, being built by ATCO in downtown Calgary. ATCO’s office trailers are ubiquitous in Western Canada, and they have plenty of experience building modular housing for work camps.

This project is a six-storey building with 84 studio apartments, two apartments per module. It took about three months for ATCO’s factory in southwest Calgary to manufacture the modules, and they’re being assembled on-site in just 10 days.

According to the stories, the speed and cost savings are remarkable. CBC News:

Jaydan Tait, CEO of Attainable Homes Calgary — the city-owned agency behind the project — says the speed of modular construction is a major advantage as Calgary tackles an ongoing housing crisis.

"From the starting point of manufacture to a fully-stacked building will be from April 15 to the middle of August, so just a few months, unlike a typical construction build which can be on average about two years," said Tait.

Compared to traditional builds, this approach requires less labour, says Tait, and the construction costs are lower since it takes less time to complete. He says that's reflected in the price charged to tenants.

"We're going to be able to rent every single studio unit, 84 studios in there, for under $1,100 a month," he said.

"So if you make about $44,000 to $50,000, you're the kind of client we want to live in this building and that's calculated on you not spending more than 30 per cent of your income on rent."

The apartments will rent for less than $1,100 a month, compared to a market rate of $1,430/month. Note that this is with some subsidy: the project received $5.5 million from the city of Calgary.

The stairs, elevators, and external cladding need to be added. The building is expected to be ready for occupancy by January 1.

Jaydan Tait on LinkedIn, August 2024:

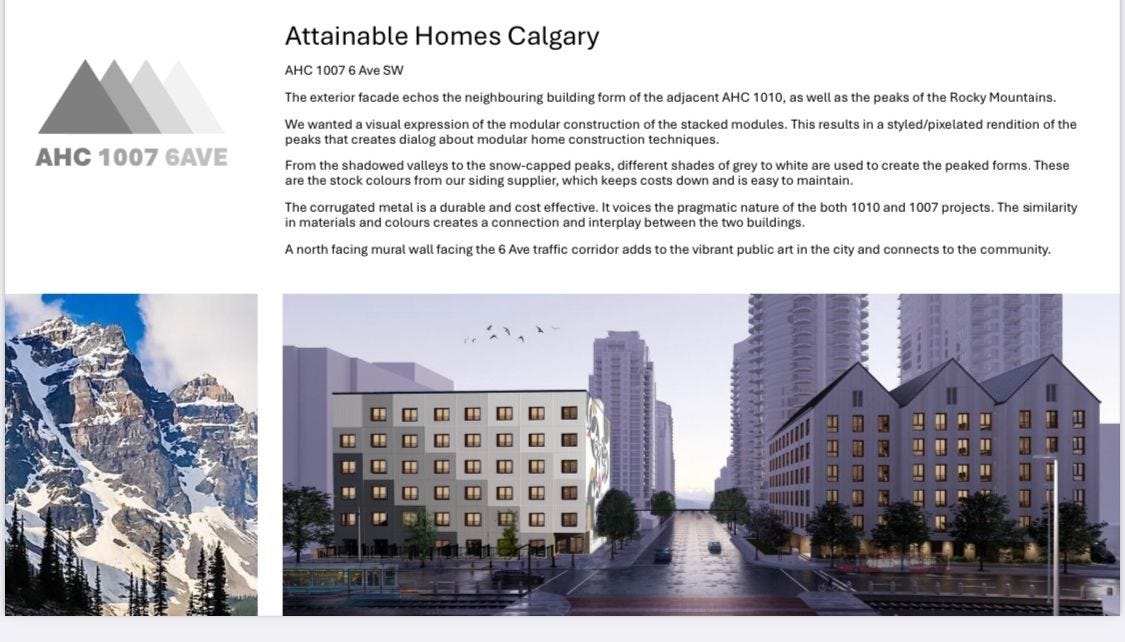

Here is a rendering of the 84 unit modular project (left), and the under-construction 1010 6 Avenue SW project (right). The design inspiration blurb is courtesy of our project partner, ATCO Structures.

The 1007 6 Avenue SW project (left), once "as-of-right" zoning is approved, can be built, delivered, assembled and occupied on site by JUNE 2025. This is just 10 months from now. The planning approval process will make up over half of that time.

In contrast, the 1010 6 Avenue SW project (right), is under construction and will be occupied next May. That classically constructed 6 storey wood-frame apartment building (with a concrete podium for parking) will take 20 months to build, plus the additional 14 months of development permit approval work.

From 3 years to under 1.

The way to produce housing of all types, at the scale of MILLIONS of homes across the country, is through local planning departments changing the way they do business to ISSUE PERMITS TO DEVELOP WHEN MINIMUM ZONING RULES ARE MET. It is pretty simple actually, and those who don't do this work for a living might be interested to know that this is NOT how planning approvals currently works.

I continue to encourage all of us in this battle to build for dignified housing to share our stories and our work, so we can all recognize and obliterate the barriers that stand in the way of creating the millions of houses Canadians need and deserve!

Some discussion of costs:

The wood buildings themselves are similar in hard cost. The concrete podium for the project under construction is a $3m premium - basically $215,000 per each of the 14 stalls we had to provide based on the old zoning. And those stalls take up space that should be houses. Any parking structure is prohibitively expensive, complicated, time consuming and - frankly - obsolete in transit-oriented development areas.

However, the huge cost savings comes in slicing project delivery time to under 1 year, from 3 years or more. You save millions on construction loan interest and other carrying costs.

What would it take to do this in Vancouver?

Uytae Lee (About Here) has a video on modular housing: Why is it So Hard to Mass-Produce Housing?

Transportation costs are a constraint. The site can’t be too far away from the factory. (ATCO and Horizon North have factories in Kamloops.)

Economies of scale are also a constraint. You need a minimum volume to justify the cost of building and operating the factory.

There’s also issues with financing (usually construction loans are based on stages of construction, which don’t apply to prefabricated homes) and inspections (similar).

Regulatory harmonization is a big one. It’s hard to mass-produce housing when regulations for each and every municipality are different.

There’s probably a whole range of subtle regulatory differences, but one obvious one in the city of Vancouver is that an apartment building is required to include 35% apartments with two or more bedrooms. So you’d need special permission to build a project like this.

More

Staff report for the project, September 2024. “This application was circulated to the public/interested parties, notice posted on-site and published online. Notification letters were also sent to adjacent landowners. No public comments were received at the time of writing this report.” Hard to imagine in Vancouver.

ATCO acquires NRB, Canada's largest modular housing builder. Neil Sharma, RENX Homes, June 2024. YouTube videos from NRB Modular, including short videos from their factories in Cambridge, Grimsby, Calgary, and Kamloops. ATCO also acquired Triple M in January 2023.

Viva Homes, an ATCO business aimed at residential housing. Floor plans for a project with 12 one-bedroom apartments and 12 three-bedroom, two-storey townhomes. The 1BR apartments are 450 square feet and the 3BR townhomes are 900 square feet. There’s 12 parking stalls on-site.

Building homes faster and better. Richard White, Calgary Herald, April 2025. Viva Homes has a fourplex model (a three-storey building with two 1BR apartments on the ground floor, two 3BR townhomes above) that can be manufactured in six weeks and placed on a 50x120 lot. “From ‘shovel to sleeping’ in 48 days.”

A Research and Markets report on multifamily modular and prefabricated housing lists some ATCO competitors.